Ford 6.0 Powerstroke Turbocharger

The turbocharger or turbo is an additional system used by car manufacturers to boost engine power. Usually, the turbocharger is found in larger cars and used to deliver the same level of power that smaller cars have. All manufacturers are now utilizing turbocharged engines in their lineups. Ford have replaced their old 1.6-litre petrol engine with the new 1.0-litre turbo EcoBoost unit – this means they can provide smaller engines that produce the same power output while also increasing fuel efficiency

The 6.0 Powerstroke was the first diesel engine produced by Ford with emissions standards. The new technology, such as EGR systems, led to a number of engine problems and ultimately gave the 6.0 Powerstroke a bad rap for reliability. Although they are controversial due to some issues, the 6.0 diesel engines can be perfectly reliable with a few upgrades.

The factory specification for the 6.0 Powerstroke included 325hp and 560-570lb-ft of torque, with both figures diminishing as they age in today’s market. In order to maximise your vehicle’s power, here are some budget and entry level modifications to consider. For a few thousand dollars, you can have 450 horsepower and 800 pound-feet of torque with your 6.0 Powerstroke turbocharger. You might also want to consider getting the engine performance kit.

Click here to skip to our recommended pick!

- Turbine Vanes: Altered for Higher Flow

- Compressor Wheel Inducer: 63.5mm

- Compressor Wheel Exducer: 88mm

- Turbine Wheel Inducer: 72.5mm

- Turbine Wheel Exducer: 66.5mm

- Value for money: 🔥🔥🔥🔥🔥

- Purchase link: Buy your Garrett Powermax Turbocharger for 04.5-07 Powerstroke 6.0L Turbo at Amazon!

- Part Number: 725390-5006S

- Turbine Wheel Exducer: 73mm

- Compressor Wheel Exducer: 82mm

- Turbine Housing: 1.12 A/R, Free Float

- 6.0L Powerstroke Diesel 2003

- Value for money: 🔥🔥🔥🔥

- Purchase link: Buy your Garrett Ford 6.0L GT3782VA Turbo for 2005 - 2007 at Amazon!

Ford 6.0L Power Stroke Engine Review

Ford’s 6.0-liter V8 turbo diesel engine has been a popular choice since its launch one year ago, succeeding the 7.3-liter Power Stroke that was considered efficient at market entry. This new version met lower NOx requirements and offered a more efficient fuel injection system as well.

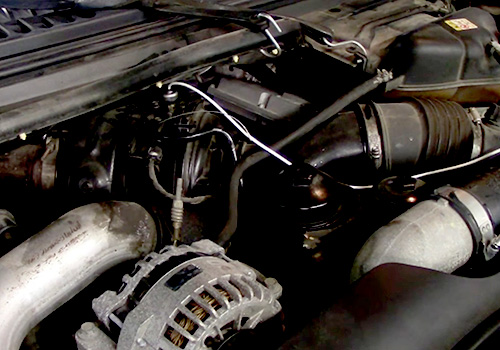

The 6.0 Powerstroke turbocharger is self-contained and integral to the engine block making it less susceptible to oil surge from blitzes or blow by from incomplete combustion. The 6.0 L engine in the 2003-2004 Ford Super Duty PowerStroke trucks was a milestone for diesel truck power, featuring powdered metal connecting rods and aluminum pistons. The back of the engine houses the gear train for both crankshaft and camshafts, as well as the high-pressure oil pump.

The 6.0l PowerStroke turbocharger received changes in 1997 that included cast iron high flow cylinder heads with four valves per cylinder. The valvetrain in the 6.0 powerstroke turbocharger head consists of a single intake runner per cylinder composed of two types of valves: 33.8 mm (1.3″) diameter intake valves and 28mm (1″) exhaust valves, each running perpendicular to one another for optimal flow and less exposure to air cooling times. The fuel and air filters were also both changed from a honeycomb-shaped element to specially shaped ones that meet up with injectors downstream or upstream so that dirt doesn’t get sucked into where it might block some airflow through them.

The 6.0 powerstroke engine features a HEUI (Hydraulically Actuated Electronically Controlled Unit Injection) and the fuel injection timing and pressure are controlled by high-pressure oil and electronics. The 6.0 PowerStroke engine is equipped with a Split-shot HEUI fuel injection system that allows it to produce high amounts of pressure during combustion. The HPOP and the turbocharger are located at the rear of the engine, while the pump is found under the RVHP cover near the front right side of the block in the outer module well.

The 6.0 engine was the first in Power Stroke family to incorporate a single variable geometry turbocharger (VGT). It has electronically controlled and hydraulically actuated vanes and a 58mm compressor wheel. The 6.0L The Power Stroke proved less reliable than the 7.3L predecessor and was replaced with a more powerful, durable, and emissions-friendly 6.4L version in 2008.

Ford 6.0L Powerstroke Turbochargers

Ford’s latest products, like the F-150 and Super Duty pickup trucks are engineered for performance. Ford builds cars with capabilities that will never disappoint you no matter the occasion or whether you’re running late for an interview or driving your loved ones to their destination. Fortunately, Ford’s turbocharger is designed to ensure a car remains reliable and efficient. Without it, there would be very little happening because the truck can only go from point A to point B and nothing else worth mentioning.

Checking out your Ford turbocharger helps ensure it still works properly. You should think about changing it if it is not delivering the power you want. It’s important to change it in order to restore your car’s integrity and overall performance, and stop more damage. You should clean your Ford turbocharger if you want it to run efficiently. You need this working at 100% for your truck to be running economically, so upgrading is necessary and will minimize any problems further.

How Do Turbochargers Function?

A turbocharger is a device that provides extra horsepower to an engine by increasing the rate at which it burns fuel. A turbocharger contains a turbine in a blower assembly or just an impeller, and unlike other motors, this one only works when air passes through it. Unlike a jet engine, turbochargers use the exhaust stream for their source of power. Air enters the front of the engine and spins inside an air-filled chamber where it’s mixed with fuel until ignited, which causes hot gases to be expelled from the back end.

The turbocharger in a diesel engine utilizes the spent fuel created when it burns to engage an air compressor that then rotates a turbine. This process increases the volume of your truck’s cylinders and forces extra air and fuel into them at unnaturally high levels. A turbocharged car can generate more power, otherwise known as energy per second. There are three units involved:

- Turbine side

- Compressor side

- Cartridge

A turbocharger consists of two components: the turbine side and the compressor side. You can see a turbine wheel and the turbine housing on one end, while a compressor wheel and the compressor housing are visible at the other end. These components are connected by what’s called a “cartridge.” A turbocharger is an air compressor that operates with an exhaust-driven turbine. Combusted fuel gases are compressed by the turbocharger, and those hot gases spin the turbine to produce the same increase in a vehicle’s air compression as if it were producing more power than its standard compression.

The turbine in a turbocharger spins on an axis, with the blades rotating at tremendous speed to harness compression power from the higher exhaust volume. The energy that has been tapped from this extremely high-pressure heat is cooled by air before it’s fed into the cylinders of your engine. Despite the motor’s turbocharger needing a few seconds to spool up when you first press down on the gas pedal, you will notice an immediate push as soon as it does. This is what is traditionally known as “lag work.”

Best Ford 6.0 Powerstroke Turbo Upgrade

Our 6.0 powerstroke turbocharger upgrade is a common upgrad for the Chevy Duramax and the Ford Powerstroke. The compressor housing needs to be machined, but if you have a 13 blade turbine then your turbine housing also requires machining- we sell individual parts shown above, or offer an upgrade service.

Ford’s 6.0 Powerstroke Diesel engine was launched in 2003 and was the first emissions-era diesel they had ever produced. The technologies found on the 6.0 Powerstroke, which include EGR systems among other upgrades, are what led to reliability problems leading consumers to believe that this particular model was unreliable on a whole.

The 6.0 Powerstroke came with 325hp and 560-570lb-ft. of torque when it debuted in 2003, but the numbers today are much more impressive as a 6.7 Powerstroke produces 425hp and 950 lb.-ft of torque. If you are looking for some additional power, here are five budget and entry-level modifications for the 6.0 Powerstroke

Garrett Powermax Turbocharger for 04.5-07 Powerstroke 6.0L Turbo

Garrett Ford 6.0L GT3782VA Turbo for 2005 - 2007

What Causes Turbo Failure?

Turbochargers are extremely reliable. Less than 1% of warranty inspections find a fault with the turbo itself; instead, blown turbos are normally the result of problems with engine lubrication or introduction of foreign objects.

OIL/LUBRICATION

The engine oil is what keeps your car running smoothly- it lubricates almost anything that moves and protects parts from corrosion.

The turbocharger needs regular, high-quality oil to stay fully functional. If the engine runs dry of oil (oil starvation), using an incorrect oil type, or if the quality of the oil is compromised for any reason, contaminants in the engine will build up and inflict abrasive damage on it over time.

In order for the car’s engine to run properly, it’s important that oil is replaced in intervals preset by the manufacturer.

DAMAGED SEALS

When the seals between the compressor and engine become worn or cracked, they allow oil to leak into the exhaust system. As a result, the turbo has to work harder to increase air pressure.

Some symptoms of over-speeding are reduced efficiency, decreased boost delivered by the turbo, and in general a reluctance to acclimate.

FOREIGN OBJECTS/DEPOSITS

A turbocharger is made up of a compressor and turbine, which are at the front and back, respectively. One of the most common issues with turbochargers is that small particles and other substances can get into the system.

Foreign objects in a turbocharger usually come from the air filter; they are less likely to originate from within the engine.

Turbines and compressor wheels give up power when they are damaged. Clean your air filter regularly to avoid this happening. Check your turbo for debris as well.

WEAR & TEAR

Turbochargers are designed to last for the lifetime of a car, around 150,000 miles, but it is possible that they wear out over time based on how hard you drive your vehicle and the original build quality.

Is it Possible to Drive With A Blown Turbo?

Yes, you’ll still be able to drive your car if your turbocharger fails. However, engine failure may follow soon after. Only drive on when necessary.

So if you notice any of the symptoms outlined above after 30 minutes or so, make sure to get your turbo checked by a qualified technician as soon as possible. The longer you wait, the more expensive (and worse) your problem will become.

How to reduce the amount of problems on your 6.0?

Upgrading your truck to a performance turbocharger is not always the best option. Unless you are experiencing one of the problems mentioned above, say no to these upgrades and focus on other areas instead like new head studs/gaskets or appointment maintenance.

Change your engine oil every 5,000 miles with high quality oil and make sure to buy the right fuel from reliable gas stations. Invest in good gauges such as an Edge CTS2 or Bully Dog GTX so that you can monitor your truck’s vital stats early on.

6.0L Powerstroke Turbocharger Removal

- Disconnect both negative cables for the battery. Next, remove intake tubing between the compressor housing and air filter including any metal brackets attached to the top of it (use a 10mm socket).

- Drain coolant from the radiator by unscrewing three hoses connected to the degas bottle and unplugging it. The degas bottle is located on the front left and underside of the engine, two bolts with a socket are required to remove it. Be careful not to over-tighten as this will break the plastic tank.

- Carefully remove the push-pins securing the harness running against the cowl from the passenger side to the driver’s side, then work it out of your way. Remove CAC (charge air cooler) tube from the hot side of the turbocharger, getting rid of hydrocarbons and harmful gasses in the process.

- Loosen the Marman clamp from one side of the turbine inlet to the up-pipe connection flange so that you no longer have V-band holding them together. Loosen and remove on another side of the turbine outlet to downpipe connection, which becomes easier with all your T-bolts removed. Position this second Marman clamp around the hose where your first Marman clamp was just removed.

- To remove the 3 V-band clamp sections, use a flat head screwdriver to pry at each of the Marman clamps – or any other prying tool that will work. Make sure you use an 11mm socket for both the downpipe and up-pipe Marman clamps.

- Disconnect the VGT solenoid connector, then remove the solenoid harness clamp mounted to the compressor housing. Position the harness aside so that it does not get snagged while removing the turbo.

- Disconnect the oil supply line from your turbocharger’s top using a 10 mm socket.

- Quit disconnecting the oil supply line from the oil cooler fitting. For later 2003 and newer models remove the collar hold down bolt and pull up on tube to disconnect. For early 2003 model year engines with quick connect fittings use an oil line removal tool (OTC 6594) by wedging the fork between rubber connector and flange, as seen pictured. When releasing it should not be too tough to remove.

- It is important to liberally spray the three bolt areas on the turbocharger with lubricant. The left-hand side bolts are visible, but the right-hand side bolt may require feeling for; it is located behind compressor housing between downpipe and up pipe.

- Loosen the turbocharger pedestal bolts (10 mm socket) with the downpipe in place. The downpipe features a small hook that loops over the turbine outlet flange. Position the downpipe so that this hook is no longer secured to the downpipe flange.

- To remove the turbocharger from the engine bay, first lift it up and side-to-side. Then maneuver it out of the space with care.

- Once the turbocharger is out of the vehicle, remove the oil drain tube sticking up next to your radiator. Use a crescent wrench to loosen and unscrew it and pull it out while rocking side-to-side.

- If you don’t want to upgrade your powerstroke turbocharger, or if you already have 2007 MY parts, replace both o-rings and clean the o-ring lands.The 2003-2006 MY model of the drain tube has a unique flange to make sure it is inserted into the high pressure oil pump (HPOP) cover correctly. For 2007 models, we need to measure out exactly how deep it needs to go.

- The mandrel bent drain tube is the preferred pipe for 2007 models, and it’s thought to be better at preventing turbocharger failures from lubrication-related issues.

- If you are planning on removing the turbocharger, remember that for a 2003-2004 MY engine, or all model years after 2004, be sure to replace the ICP sensor before you do. The IPR valve is also hidden behind the rear intake runner and can only be reached with extension tools.

6.0L PowerStroke Turbocharger Installation

Re-installing the turbocharger is more complicated than removing it – work slowly and do not attempt to force the turbo into place. Thoroughly clean both surfaces of the gasket mating surface on top of the turbocharger, removing all remnants of the old gasket.

Clean and coat the o-rings with 15W-40 motor oil, then insert the tube into the HPOP cover. Insert it until you cannot go any farther (2003 – 2006 model year).

2007 6.0 Powerstroke turbocharger: Draw a line 0.9″ from the edge of the tube on the side that inserts into the HPOP cover. It is important that the drain tube does not insert past your reference line on the housing. Apply clean 15W-40 motor oil to the o-rings in order to make installation easier, and then install the tube without inserting it all of the way inside until you reach your reference line (about half way should do). This will make it easier to reinstall this hose into your turbocharger.

As a turbocharger will be heavy, it may take more than one person to complete this step. If you have someone handy, they can hold the base of the turbine housing as you position the top end of the central shaft and push it into place with an open-ended wrench. For 2003-2006 PowerStroke diesel models, make sure the drain tube is securely embedded into the cover of the high pressure system.

For 2007 MY drain tubes, push the tube into the HPOP housing up to the reference line. Do not over-insert or pull out once inserted, as it may damage the o-ring. 0.9″ is International’s spec, but there is some leeway here.

Ensure the up-pipe is aligned with the turbine inlet flange and that the down pipe aligns with the turbine outlet flange (including the hook on the down pipe).

Assembly Tip: When installing the turbocharger on the pedestal, use torque-free or anti-seize lubricant to help it twist and prevent future corrosion.

Place the Marman clamps on the downpipe and up pipe. Then clamp securely in place by torquing both clamps to 89 inch-pounds. After several drive cycles, re-torque these clamps periodically (89 inch-pounds). Make sure flanges are aligned and not misaligned or damaged. Make sure the turbocharger is securely fastened to the pedestal. The mounting bolts should be tightened, and torque set at 28 lb-ft.

Eddy current bearings are lubricated by oil, and a turbocharger draws its supply from the engine or an external supply. When installing the engine internally, attach a feed line to bring in the oil externally; when using an external pump, connect both lines for maximum flow. To give it extra protection against corrosion, pre-lube the turbocharger at assembly with clean motor oil – just 1/8 to 1/4 liters will do – then spin the compressor wheel to circulate it around and through all bearing surfaces while pulling on any belts connected to see if there is slippage.

If your truck is 2003+, replace the oil supply line and use 15W-40 motor oil. If it’s from 2003, clean out the old o-ring, instal a new one along with gasket to turbocharger; then install the hydraulic line into fitting neatly in the engine valley. Then align both sides of the turbocharger shaft and tighten up bolts on the hydraulic lifeline as they are approximately 18 ft lbs for those model years.

With the vacuum lines disconnected, use a tie wrap to temporarily and carefully secure the Vacuum valve connector (VAC) solenoid harness bracket. Reinstall the hot side cold air tube. Clean any oil residue from either end of the hose before tightening up all connections with an inspection mirror in place for visibility.

Remove the degas bottle, refill it and then re-install the bottle with new coolant lines. Make sure to position the wiring harnesses lower to avoid any potential for stress on them that could occur when tightening down some bolts.

Disconnect the wiring harness from the cowl. Connect all of the intake plumbing to the engine. Reinstall any clamps that were previously loosened and ensure no leaks are present when starting up the engine. Check for evidence of leakage after several drive cycles have taken place, then re-torque any loose couplings.

Conclusion

Whether you own a Ford Fiesta, Focus, Taurus or another model of this car manufacturer, it may be time to get your turbocharger changed. We have an inventory with the best turbochargers out there from high-quality brands that focus on performance and quality.

The Ford turbochargers we provide are sold at competitive rates and our team of experts will ensure you find the right one for your vehicle. Our focus on quality ensures that every component is tested thoroughly, giving you peace of mind.